Ancon Teplo Basalt Fibre Wall Ties

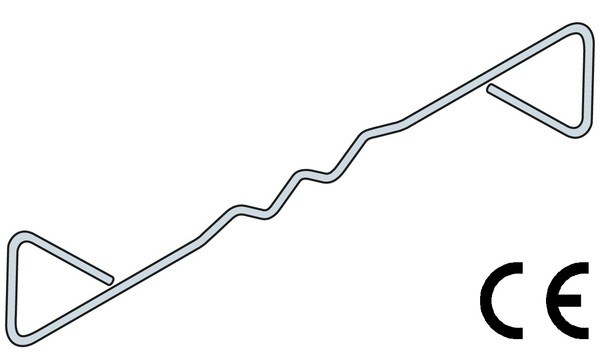

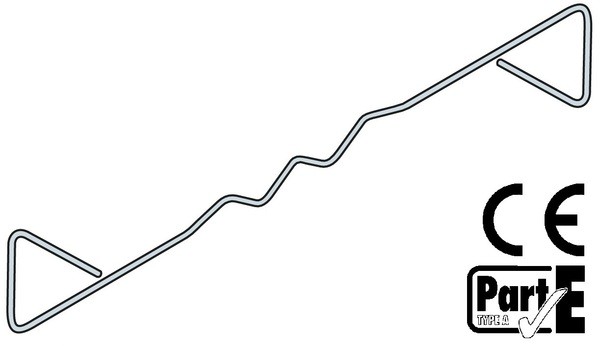

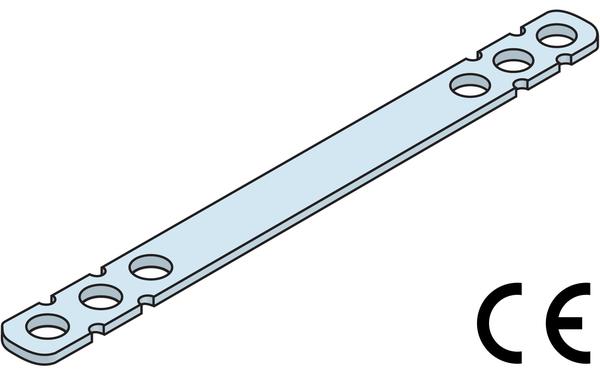

The Ancon Plain-Ended Teplo Ties, the original basalt-fibre wall tie Tpes 1,2,3 & 4. They can be used in new-build cavity applications and resin-fixed in remedial/retrofit projects.

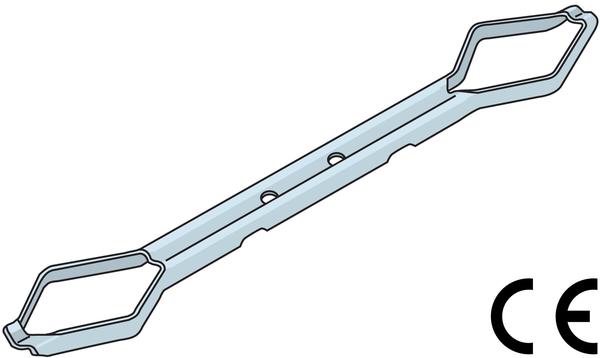

The Ancon Teplo-BF Type 1 is a composite wall tie manufactured from pultruded basalt fibres. It has a thermal conductivity of 0.7W/mK. The type 1 Teplo-BF1 is BBA-approved in lengths of 200, 225, 250 and 275mm to suit cavities from 50mm to 150mm.

The Ancon Teplo-BF Type 2 is a composite wall tie manufactured from pultruded basalt fibres. It has a thermal conductivity of 0.7W/mK. The type 2 Teplo-BF is BBA-approved in lengths of 200, 225, 250, 275, 300, 325, 350, 375, 400 and 425mm to suit cavities from 50mm to 300mm.

The Ancon Teplo-BF Type 3 is a composite wall tie manufactured from pultruded basalt fibres. It has a thermal conductivity of 0.7W/mK. The type 3 Teplo-BF is BBA-approved in lengths of 450, 475, 500 and 525mm to suit cavities from 301 to 400mm

The Ancon Teplo-BF Type 4 is a composite wall tie manufactured from pultruded basalt fibres. It has a thermal conductivity of 0.7W/mK. The type 4 Teplo-BF is BBA-approved in lengths of 200, 225 and 250mm to suit cavities from 50mm to 125mm, and 550mm and 575mm to suit cavities from 401-450mm.

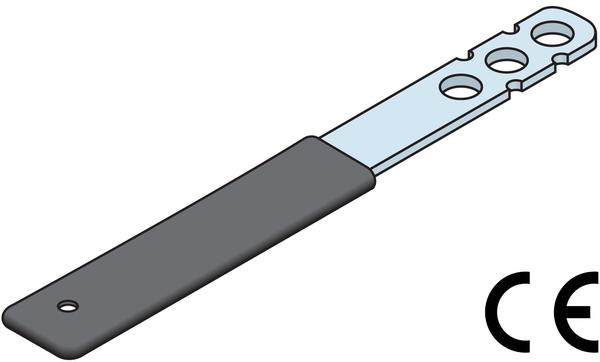

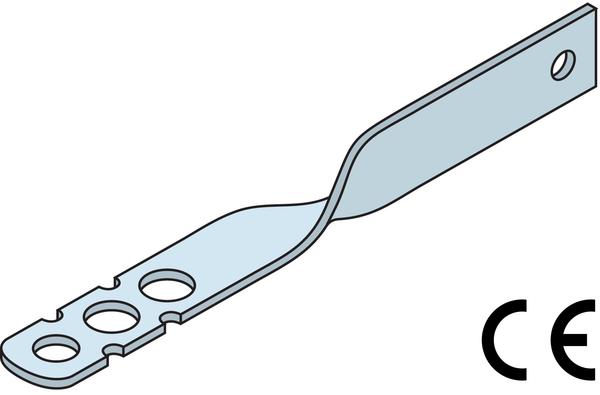

The Ancon Teplo-BFR Tie is a low thermal conductivity wall tie manufactured from basalt-fibres that features a plain end for resin anchoring into an existing structure and a moulded safety end for building into a new bed joint. It is ideal for new-build cavity wall construction where mortar joints do not align e.g. thin-joint blockwork, or in retrofit applications where a new leaf of masonry and insulated cavity is being constructed against a pre-existing masonry or concrete wall. Available in 16 standard lengths, Teplo-BFR is suitable for cavities from 75mm to 450mm. The design embedment is 70mm in the inner leaf (resin) and 65mm in the outer leaf (mortar). It is a 7mm diameter wall tie, requiring a 10mm drill bit/hole. Tie Type to PD6697 is dependent on the strength of the substrate and a pull-out test is recommended on site. Our test programme indicates Type 1 in 75-150mm cavities, Type 2 in 175-300mm cavities, Type 3 in 325-400mm cavities and Type 4 in 425-450mm cavities.