RiveStop System

An Innovative Solution For Concrete Tie-Bolt Hole Sealing & Waterproofing

The RiveStop System is a patented mechanical waterproofing system which has a unique design method of sealing tie-bolt holes in concrete walls.

RiveStop uses a patented elastic rivet with an internal mechanical waterproofing system designed to hermetically seal form tie holes in concrete structures. The system delivers savings of up to 90% on labour and material costs compared to other alternatives systems on the market. The video below shows the simplicity and speed of the system. We can provide a demonstration on site if required.

RiveStop expands inside the formwork tie hole exerting force against the walls of the hole, thus sealing it completely. The mechanical system is activated with a riveter with uniform and controlled pressure. Once the pin of the rivet breaks off, the RiveStop is installed with a 100% watertight finish.

The process is simple, quick, clean and east to check and installation can be undertaken in any weather conditions. Movement of the structure does not effect the performance of the seal and the system comes with a choice of water resistance and finish. Another benefit is that the system can also be used in combination with RivePipe to eliminate possible water path on the outside of plastic sleeving.

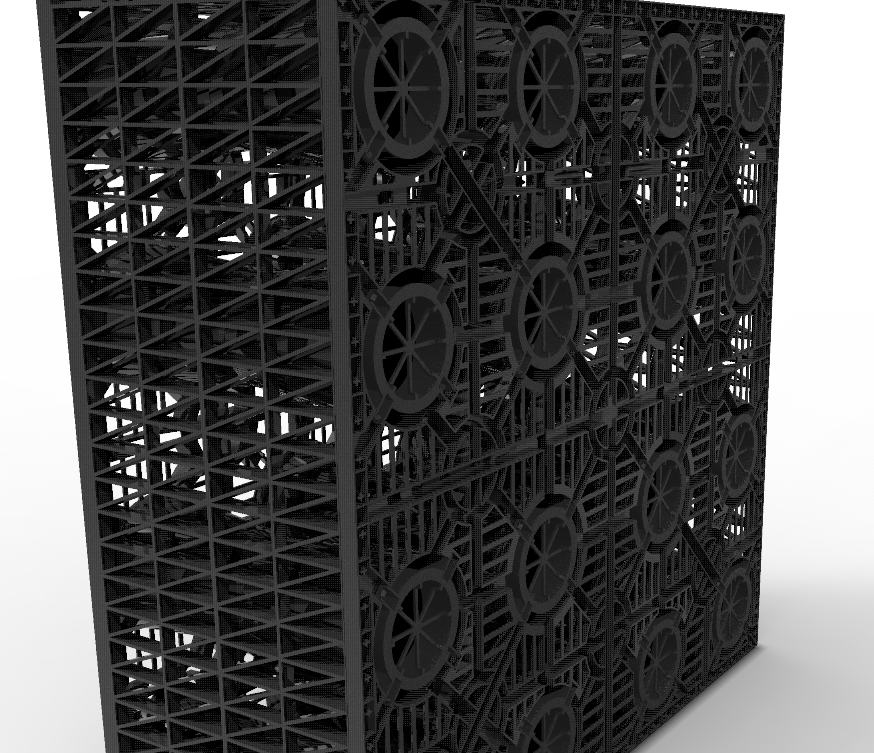

The system is comprises of three simple elements:

- RivePipe – A removable, reusable and recyclable formwork tube that protects tie bars within the concrete, and once removed leaves a clean, uniform tie hole.

- RiveOut – The manual extraction tool for easily removing RivePipe tubes from concrete walls in a matter of seconds.

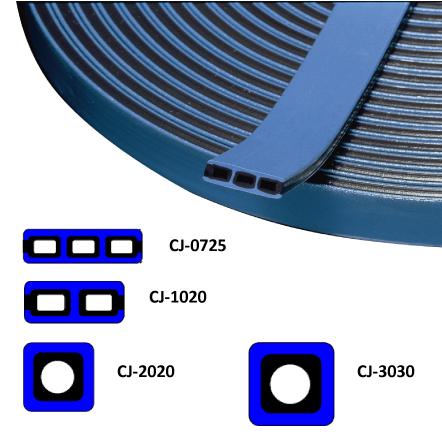

- RiveStop – A patented rivet system that is quickly and easily installed, expanding to 50% of its original diameter to hermetically seal any tie-bolt holes left by the RivePipe.